Japanese machining manufacturers are internationally recognized for their advanced industrialization and innovative technological developments. The latest trend is that the market for factory automation and industrial control equipment is expanding due to its integration with digital technology. This includes the introduction of Industrial 4.0 and the IIoT, increasing the adoption of robots and automated systems. Challenges include technology implementation costs and challenges to integrating innovative systems

Several Japanese companies are known for their proactive approach to factory automation. One prominent example is Fanuc, renowned for its robotics and automation solutions. Other notable names include Mitsubishi Electric and Yasukawa Electric, which are also key players in the industrial automation field, offering a range of automation products and systems. These companies have been instrumental in advancing factory automation both domestically and globally. For detailed information about their contributions and products in factory automation, it would be beneficial to visit their official websites or read industry reports on this sector.

Computer Numerical Control(Fanuc)

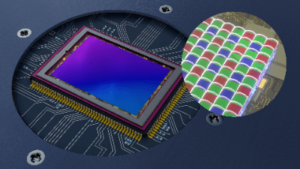

Fanuc is renowned for its highly advanced automated systems such as robotics and computer numerical control (CNC) systems. An example of Fanuc’s contribution to factory automation includes their RoboDrill machines, which are compact CNC milling machines known for precision and reliability. Fanuc also offers RoboCut wire-electric discharge machining, and RoboShot for electric injection molding, all designed to improve productivity and efficiency in manufacturing processes.

https://www.fanuc.co.jp/ja/product/cnc/index.html