OKI announced its medium-term management plan from May 2023 to the fiscal year ending March 2026, focusing on strengthening initiatives to generate “new buds of growth.” In addition, in November 2023, it also disclosed its innovation strategy to systematically foster these new buds. They aim to promote “participation by all” in innovation while actively engaging with external partners to refine the technologies owned by OKI. The recently held “OKI OPEN LAB 2024” is part of this effort, aiming to foster new innovations by showcasing advanced and fundamental technologies currently under research and development by OKI.

Mr. Takahiro Mori, Representative Director, President, and CEO of OKI, emphasized, “OKI has tended to be too closed and do everything internally. However, considering the need to significantly grow the business, external expertise becomes crucial, and that’s where we were weak. ‘OKI OPEN LAB’ is an initiative conscious of open innovation. By actively showcasing our efforts externally, we want to collaborate to create new value together. Of course, there are risks in disclosing advanced technologies externally, but we want to seize opportunities without being overly cautious and drive forward.”

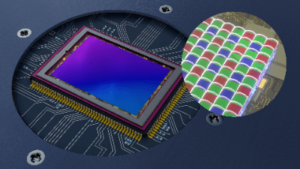

Among the introduced technologies, one that has attracted attention due to its uniqueness and wide applicability is the proprietary industrial camera lens utilizing Micro Lens Array (MLA) technology. This proprietary MLA industrial camera lens technology leverages the expertise accumulated by the company in LED printers. It utilizes information obtained from multiple lenses to simultaneously focus on objects at different distances from the lens. Additionally, it can adjust angles and other parameters to capture images. For example, even in cases where components with varying heights, such as electronic circuit boards, are present, this technology can precisely focus on all components and conduct inspections accurately, thanks to the absence of angle distortion.

Among the introduced technologies, one that has garnered attention for its uniqueness and broad applicability is the proprietary industrial camera lens utilizing Micro Lens Array (MLA) technology. This unique MLA industrial camera lens technology leverages the expertise developed by the company in LED printers. It utilizes information gathered from multiple lenses to simultaneously focus on objects with varying distances from the lens. Additionally, it can adjust angles and other parameters to capture images. For example, even in scenarios with mixed components, such as electronic circuit boards where some components have varying heights, this technology can precisely focus on all components, ensuring accurate inspections due to the absence of angle distortion.

The industrial camera lens utilizing proprietary MLA technology boasts approximately five times the depth of field of a conventional Contact Image Sensor (CIS), enabling imaging even at distances of 50mm or less from the subject to the sensor. This capability allows for space-saving, as it can reduce the size to approximately one-third compared to conventional lens configurations.

Source: Monoist

https://monoist.itmedia.co.jp/mn/articles/2403/15/news077.html