As part of efforts to alleviate labor shortages, the introduction of AGVs (Automated Guided Vehicles) in the manufacturing industry has been progressing. While the adoption of AGVs in factories and warehouses is becoming commonplace, their implementation in pharmaceutical factories, where manufacturing and quality control standards are particularly stringent, has been challenging.

In this context, Daito, a pharmaceutical manufacturer based in Toyama City, Toyama Prefecture, has introduced AGVs into its own pharmaceutical factory to improve operational efficiency.

The company’s main business pillars are the production of active pharmaceutical ingredients (APIs) and pharmaceutical formulations, with approximately 90% of its transactions involving domestic pharmaceutical companies. Daito is one of the few pharmaceutical manufacturers in Japan that handles a wide range of products, from APIs to formulations, as reflected in its slogan, “From APIs to formulations.”

Daiichi’s headquarters boasts a vast site, including six API buildings, nine formulation buildings, and three API packaging buildings. Annually, they produce approximately 3 billion tablets, around 100 tons of APIs, and roughly 180 tons of granules. Given the stringent quality and hygiene requirements for pharmaceuticals, they have established a rigorous quality management system.

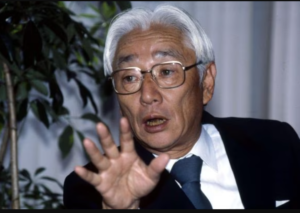

Kiyotaka Jodo, Executive Officer and Head of Production Department, as well as Director of the Environmental Safety Division at Daito, emphasized, “We undergo regular inspections from various companies, including major pharmaceutical companies, and consistently produce under strict management. We have also undergone inspections by the U.S. Food and Drug Administration (FDA), considered the most stringent in the world, and have built trust as a manufacturing company.”

Daito began implementing AGVs for transportation between the Fifth Formulation Building and the Sixth Manufacturing Building. At the first floor of the Fifth Manufacturing Building, the mixed powder is processed into tablets, which need to be transported to the fifth floor of the Sixth Formulation Building. Then, the finished tablets are transported back to the first floor of the Fifth Formulation Building for inspection.

Previously, this transportation task was carried out manually, with workers loading the items onto pallet carts. However, the total weight of the cargo sometimes exceeded 500kg. Maintaining balance was difficult, and since the transport pathway was shared with pedestrian walkways, attention was needed to avoid collisions with obstacles and cargo spills. Although the round-trip distance was 340m, narrow pathways led to waiting times during pedestrian traffic, resulting in approximately 20 minutes for the round trip. This highlighted the need for streamlining and improving efficiency.

Ms. Mika Kaguraki, Acting Section Manager of the Formulation Section in the Production Department of Daito, reflects on this: “This transportation task occurred 5 to 6 times a day. With time constraints for the next process, transportation tasks that could not afford to damage the product were extremely stressful.” To alleviate this burden, they initiated nighttime automated transportation (unmanned transportation) as the first step.

Source: Monoist

https://monoist.itmedia.co.jp/mn/articles/2401/15/news001.html