In the realm of essential “connecting” technologies crucial for realizing smart factories, MECHATROLINK stands out as a Japanese-origin open-motion field network that links various equipment and controllers. With the advancement of IoT (Internet of Things) and AI (Artificial Intelligence) technologies, the scope of factory smartification is expanding. MECHATROLINK contributes to system acceleration and enhanced functionality by ensuring high-speed communication and synchronization.

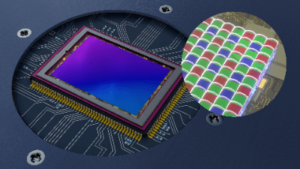

The essence of smartification lies in gathering and analyzing data, leveraging it for productivity enhancement, preventive maintenance, and even managerial decision-making. This entails not only precision and speed in equipment control but also harnessing data from the lowest levels. In this regard, Σ-LINK II network enables the unified collection of servo and various sensor information using encoder communication.

The MECHATROLINK Association, dedicated to promoting the proliferation of MECHATROLINK, introduced the latest versions of MECHATROLINK-4 and Σ-LINK II at the “International Industrial Fair for Automation and Measurement” (IIFES 2024) held from January 31 to February 2 at the Tokyo Big Sight. The theme was “Unlocking Smart Factory Realization with Next-Generation Industrial Networks,” showcasing the features and advantages of these networks. A dedicated section was also set up for member companies developing MECHATROLINK-compatible products, featuring product displays and demonstrations from companies such as Yaskawa Electric, Movensys, Oriental Motor, Yokogawa Electric, Keyence, Micro Technica, and SysTech.

Alongside seven member companies, numerous product exhibitions and demonstrations were conducted to promote the features and advantages of MECHATROLINK

Yaskawa Electric showcased MECHATROLINK-4 compatible products, focusing on their latest releases unveiled in January 2024. The “YRM1010” represents the latest model of the “move to action” YRM controller, which integrates control of cells comprehensively while collecting highly synchronized data in real-time for feedback. This product adopts a distributed architecture, enabling easy realization of data-driven autonomous decentralized control for cells. Its processing performance is approximately 1.5 times higher compared to previous models, and it can connect up to 128 stations with enhanced communication capabilities.

The “MPX1310,” successor to the MP3000 series of machine controllers, achieved significant performance and functional improvements. It boasts an eightfold increase in motion processing performance compared to previous models and expands the controllable axis count from 16 to 128. At the exhibition, a demonstration showcased the synchronization of YRM1010 and two MPX1310 units connected via MECHATROLINK-4, allowing each controller to perform motion operations with synchronized timing and cooperative control.

A representative from Yaskawa Electric stated, “In pursuit of the solution concept ‘i3-Mechatronics,’ we will continue to solve challenges in production sites and companies, providing customers with optimal solutions.”

Source: Monoist

https://monoist.itmedia.co.jp/mn/articles/2402/29/news006.html