For manufacturing industries, maintaining the value of products after sale can be seen as an inherent challenge. Since manufacturing operates on a model of creating and selling goods, the value of a product, even if it incorporates cutting-edge technology at the time of release, diminishes over time as newer technologies emerge. While this has been traditionally accepted given the development timeline of products, Mitsubishi Electric’s laser processing machine business has tackled this structure and presented a new strategy.

Mitsubishi Electric has introduced the “GX-F Evernext Strategy” for its flagship model, the “GX-F” series of 2D fiber laser processing machines. Under this strategy, the company plans to provide new features incorporating cutting-edge technology annually, enabling users to continually upgrade their machines’ performance without replacing the entire unit. Users can add new software and hardware to their existing machines, allowing them to access the latest technology and features without purchasing a new unit.

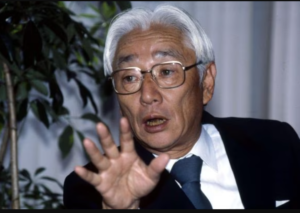

In a discussion involving Shigeru Yokoi, Deputy General Manager of the Laser Manufacturing Department at Mitsubishi Electric’s Industrial Mechatronics Production Plant, Yasushi Kobayashi, Head of the Mechatronics Business Promotion Department in the FA Systems Business Division’s Mechatronics Strategy Group for Laser Processing Machine Business, and MONOist Editor-in-Chief Kazutaka Mishima, the panel delved into this groundbreaking new strategy.

Source: Monoist

https://monoist.itmedia.co.jp/mn/articles/2301/10/news010.html